King Son's environmental testing chambers that meet the requirements of international testing standards is designed in with surface temperature detection and temperature cycle temperature change rate by testing specimens to conduct product's liability testing.

King Son 's Advanced Series THS, TSC, ATSK, HAST+ testing chambers leads the industry with superior technology.

The specific requirements by international testing standards on the surface temperature control of testing specimens include JESD22-A104F, IPC9701, IEC60068-2-14, IEC60068-3-5.

THE SURFACE TEMPERATURE DETECTION OF THE SPECIMENS (DUV, DEVICE UNDER TEST) AND APPLICATIONS

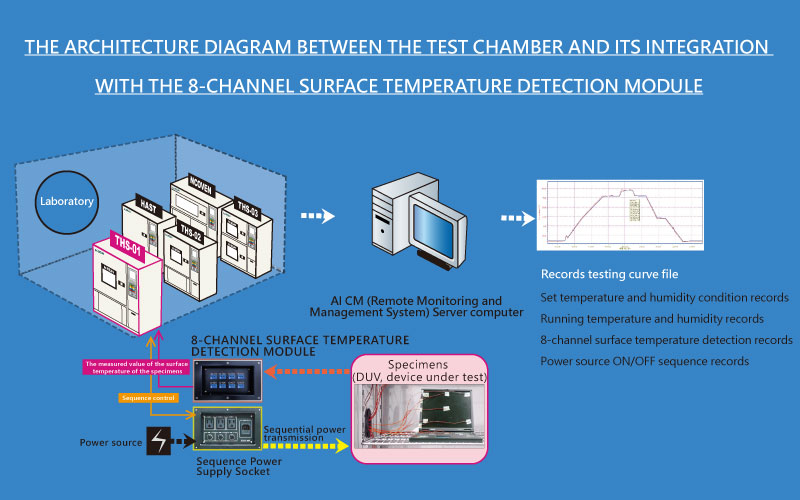

The surface temperature detection module is designed and incorporated with 8-channel temperature sensor to record the testing curve to replace the traditional 2-channel temperature sensor and surpass the industry level, which is more conducive to discover hot spots and temperature changes at various points in experiment test.

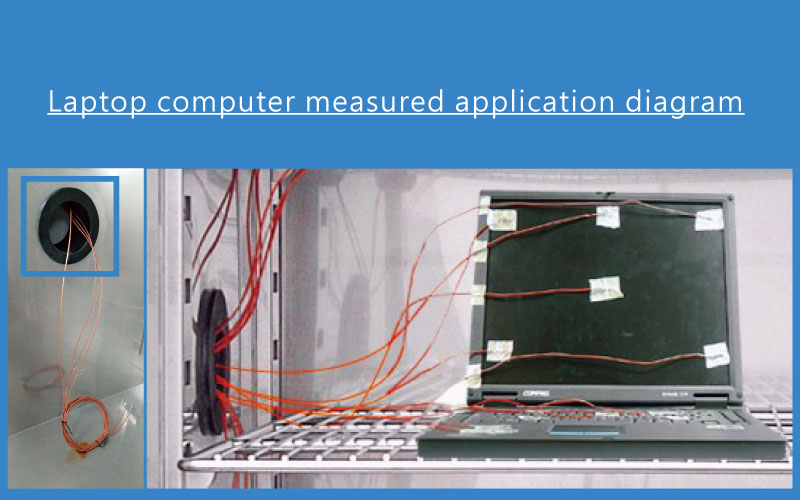

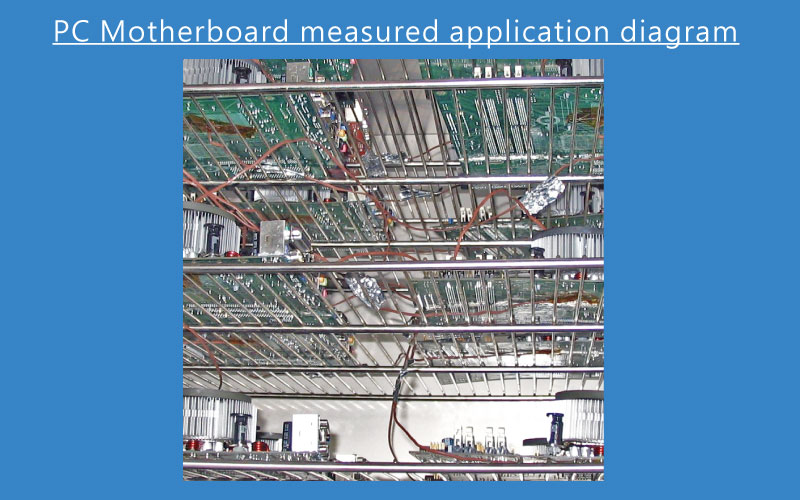

The 8-channel temperature sensor is attached to the surface of the specimens, which can be applied to the testing process such as high temperature and high humidity test, dew (condensation) test, temperature and humidity combination test, slow temperature cycle test, etc., that measure the surface temperature or internal temperature of the specimens.

The surface temperature detection module can measure, record and consolidate the setting conditions, actual testing temperature and humidity, and the surface temperature of the specimens together into a synchronous testing curve file for subsequent analysis and storage.

When the surface temperature of the specimens (DUV, device under test) reaches the temperature of the testing condition, the Chamber starts humidification on the surface of the specimens until it is higher than the dew point temperature to ensure that specimens does not condense during test.

Pre-alert and alarm for over-temperature of the specimens (DUV, device under test)

To protect the specimens (DUV, device under test) free from overheating damages, the Chamber is designed with the upper limit temperature warning function and configured with an overheating protector as the standard feature.

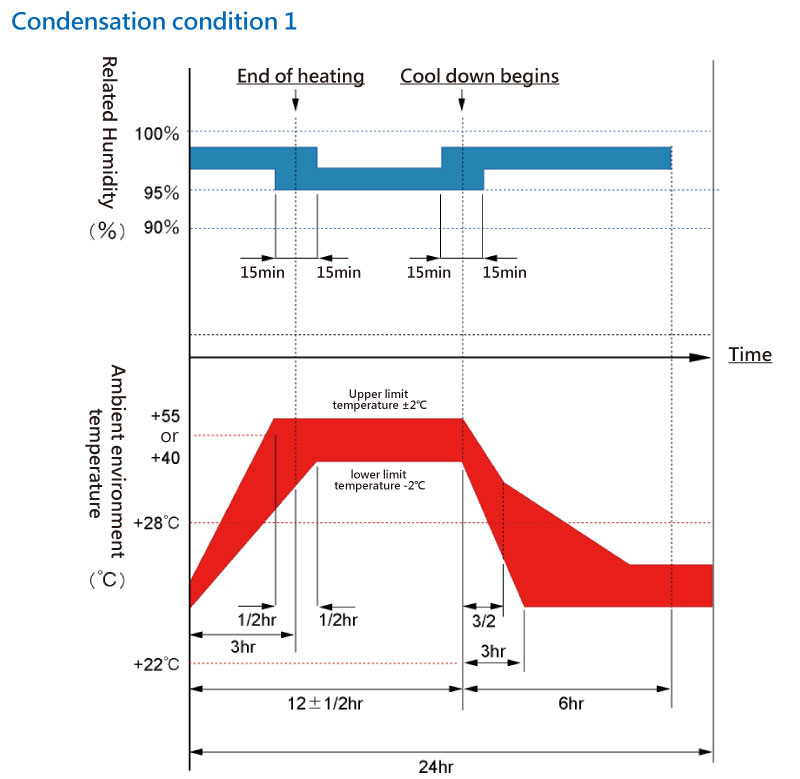

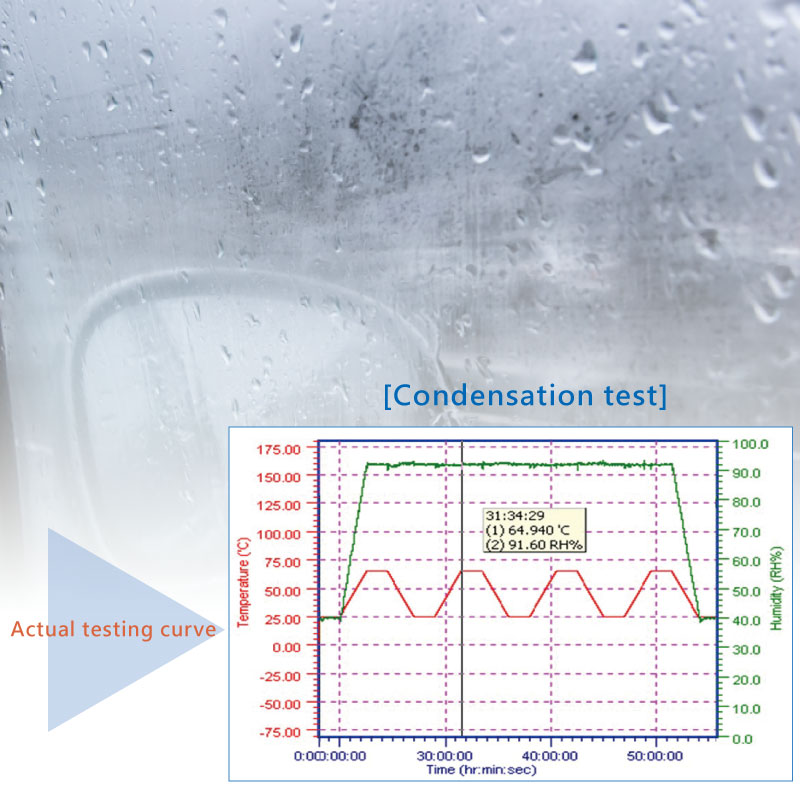

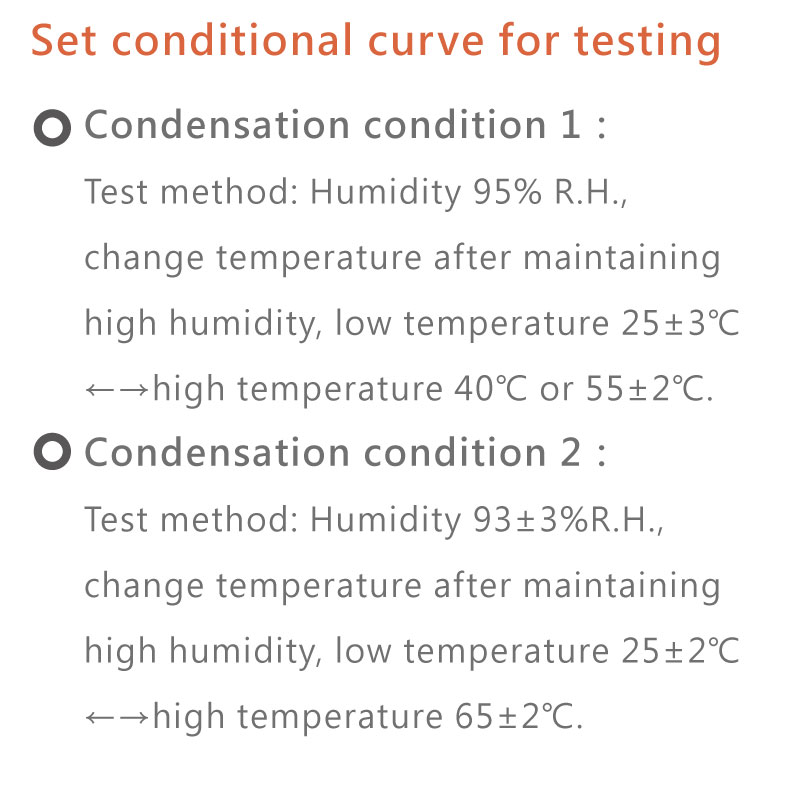

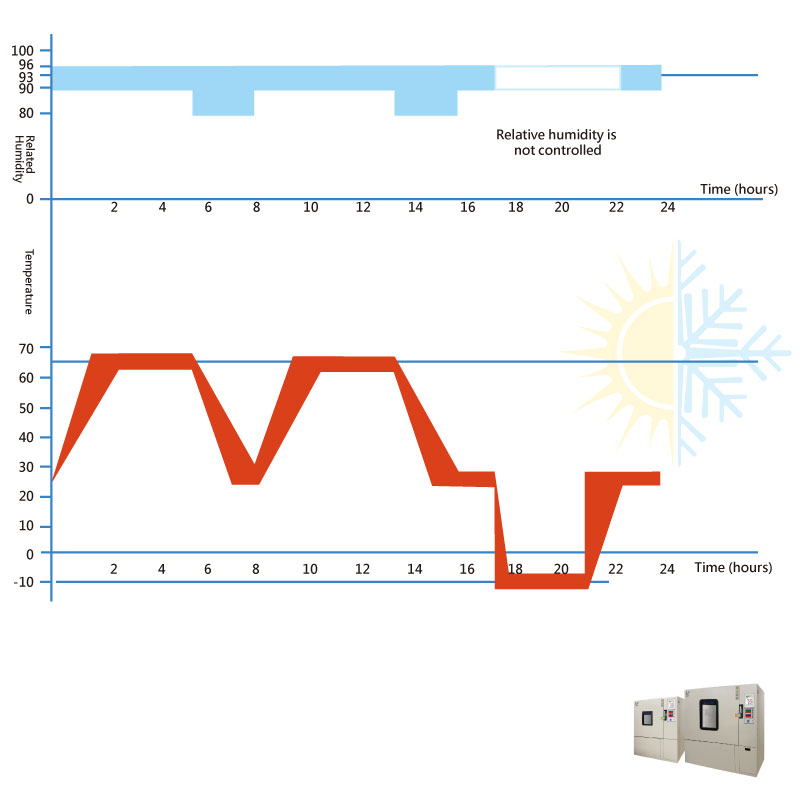

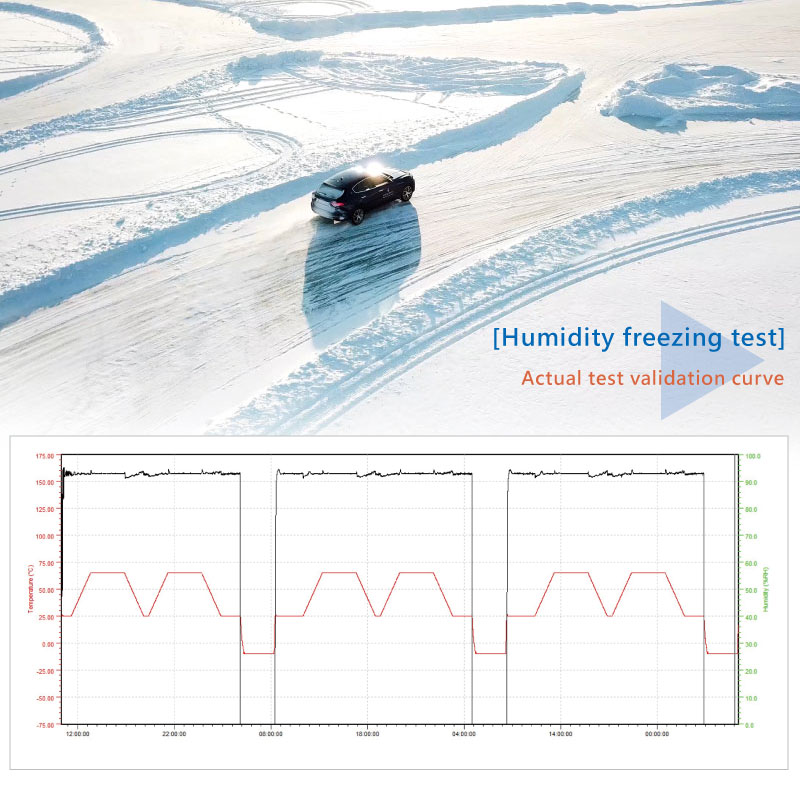

THE CHAMBER IS DESIGNED TO CONDUCT CONDENSATION & HUMIDITY FREEZING TEST FOR OUTDOOR ELECTRONIC PRODUCTS AND AUTOMOTIVE ELECTRONICS.

In addition to the fixed-point temperature and humidity test, King Son THS Constant Temperature and Humidity Chamber can conduct the condensation and humidity freezing test required by outdoor electronic products and automotive electronics, that the condensation occurs on the surface of the specimens (DUV, device under test) and simulate outdoor condensation phenomenon, thru that to evaluate material capacity to prevent water vapor diffusion, humidity freezing test to accelerate product resistance to deterioration.