AI Server cloud computing and storage industry

The difference between the high temperature produced by the operating AI server and the temperature generated by the running traditional server is relatively large, this is because the AI server needs to process many images and High-performance computing (HPC), AI Server needs much more higher processing power and more hardware resources. Hardware resources will generate a lot of heat during operation. The high temperature produced by AI servers is usually several times higher than that of traditional servers. Therefore, a better heat dissipation system is needed to maintain the stable operation of the AI server.

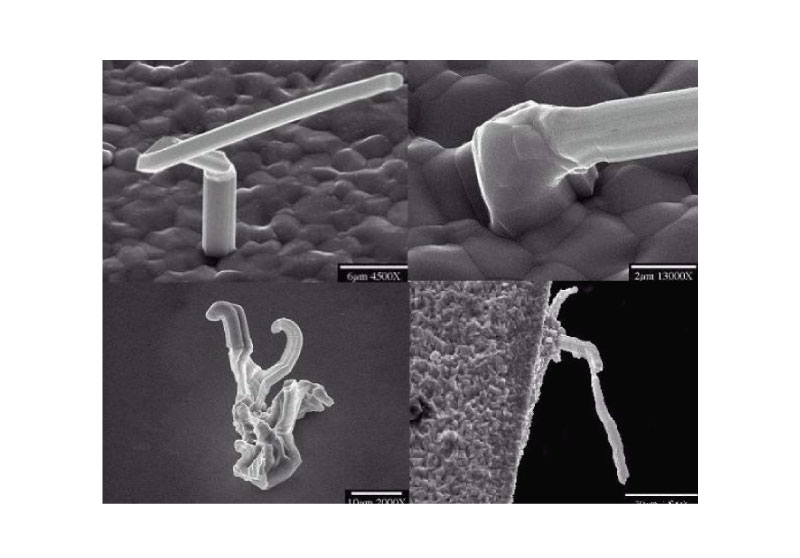

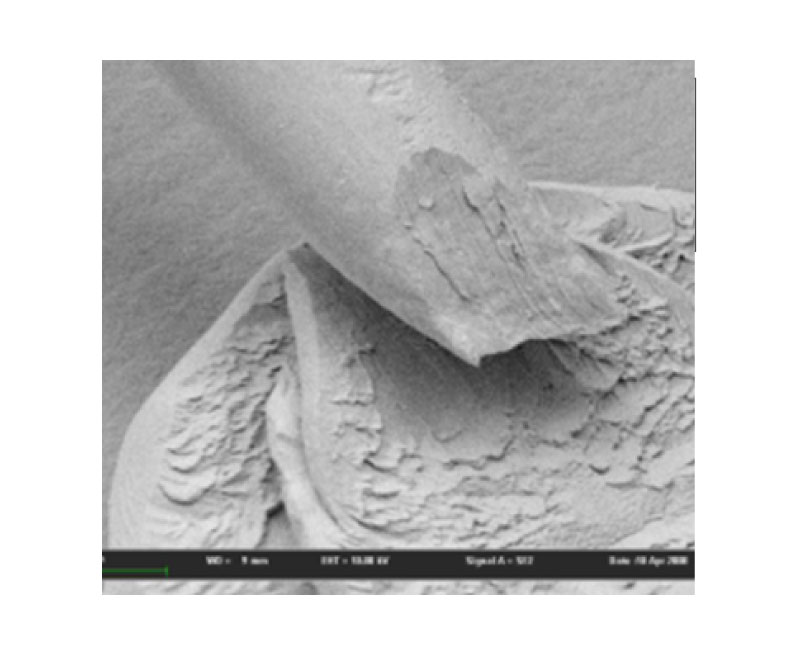

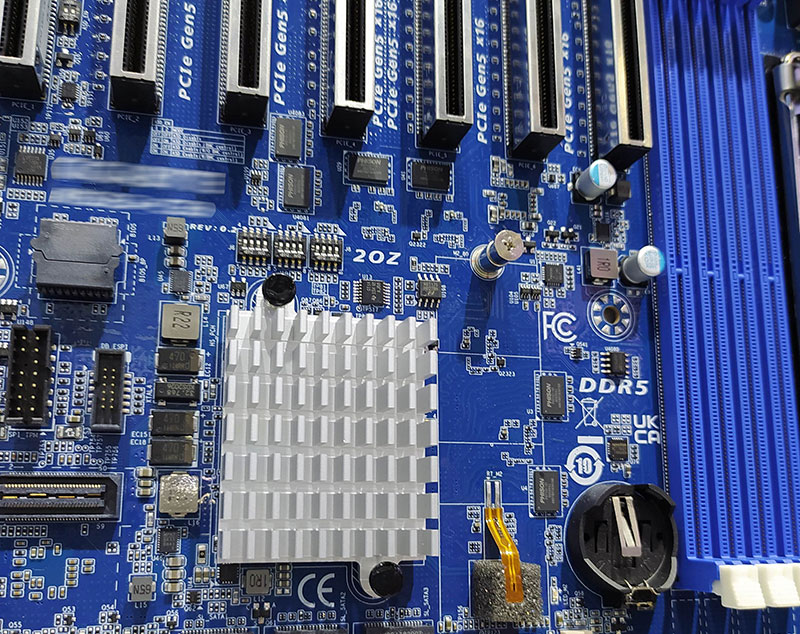

To ensure that the high temperature produced during AI server operation will not cause damage to related components and its soldering on PCB joints, it is necessary to require appropriate heat dissipation measures and reduce the temperature fluctuation range. Excessive temperature fluctuation and high current will accelerate the growth of tin whiskers. Tin whiskers refer to tiny whiskers that appear on electronic components, which can lead to short circuits or intermittent failures. In AI servers, the use of lead-free soldering processes and materials also increases the possibility of tin whiskers. The lead content in lead-free solder is lower than the traditional lead, therefore, the melting temperature of lead-free soldering is higher than the traditional one. These stresses (such as thermal stress, chemical stress, mechanical stress) will lead to accelerate the growth of tin whiskers.

King Son Environmental Test Chambers and Solutions for 5G Wireless Communication System

Through its OEM/ODM project partnership co-operation with Top 10 Taiwanese EMS (Electronic Manufacturing Services) giants accounting for 75% EMS business globally and leveraging the advantages of Taiwan’s critical role in making 90% of most advanced semi-conductor chips, King Son’s proprietary environmental test chamber and solution are uniquely positioned to play a leading role in the innovation value chain of established technology players like Apple, Dell and HP and upcoming disruptors within the

AI Server Cloud Computing and Storage Test Chambers and Solutions sector.

Rising Global Demand

AI server shipments are set to rise in 2023, boosted by robust demand and NVIDIA's market dominance. Emerging Chatbots and pricier GPU models like NVIDIA's H100 & H800 are expected to fuel a 50% growth surge!

Download the Catalog

To ensure that the high temperature produced during AI server operation will not cause damage to related components and its soldering on PCB joints, it is necessary to require appropriate heat dissipation measures and reduce the temperature fluctuation range. Excessive temperature fluctuation and high current will accelerate the growth of tin whiskers. Tin whiskers refer to tiny whiskers that appear on electronic components, which can lead to short circuits or intermittent failures. In AI servers, the use of lead-free soldering processes and materials also increases the possibility of tin whiskers. The lead content in lead-free solder is lower than the traditional lead, therefore, the melting temperature of lead-free soldering is higher than the traditional one. These stresses (such as thermal stress, chemical stress, mechanical stress) will lead to accelerate the growth of tin whiskers.

Know More

King Son Environmental Test Chambers and Solutions are ready for AI Server Cloud Computing and Storage Device's testing and development.

◆ King Son THS Programmable Constant Temperature and Humidity Test Chamber (Standard Type)

◆ King Son ATSK Thermal Shock Tester (Air to Air Type)

◆ King Son HAST+ Highly Accelerated Stress Test Chamber

◆ King Son SIR Surface Insulation Resistance Measurement System

◆ NC OVEN Chamber System

King Son offers temperature and humidity testing chambers that aid in determining reliability of the product based on rigorous conditions it may be prone to due to temperature conditions.

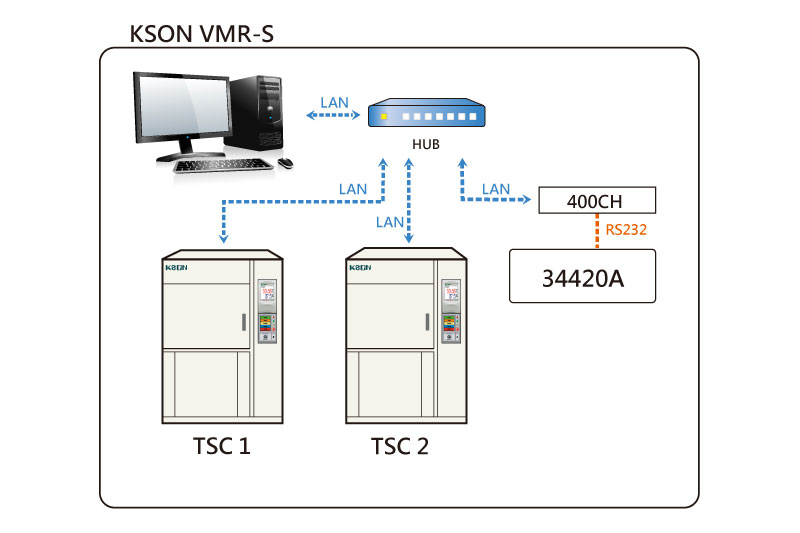

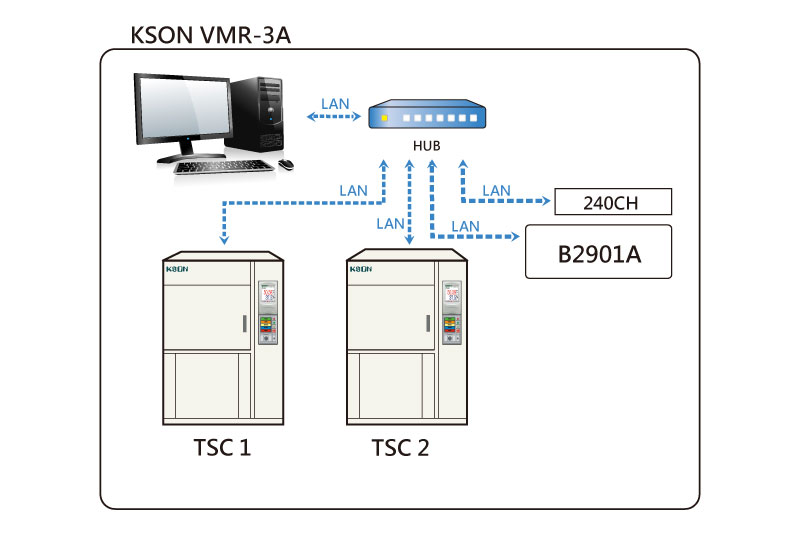

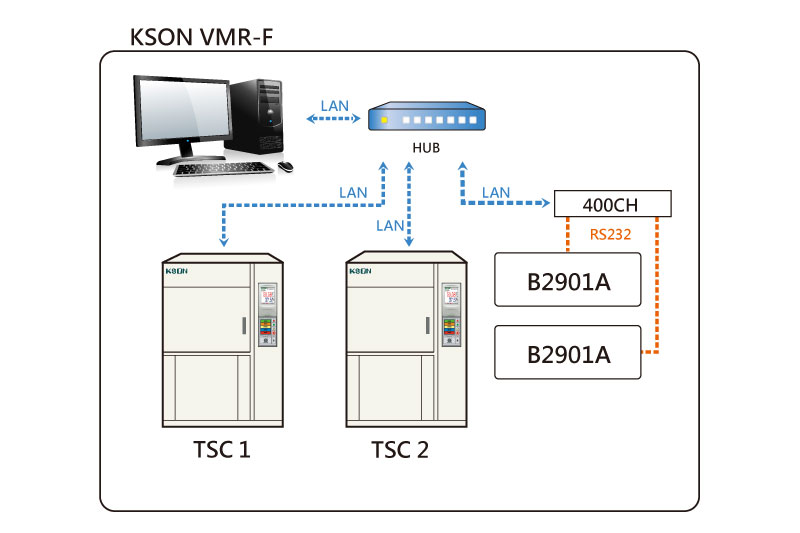

For example, the novel King Son VMR series (VMR-S, VMR-F, VMR-3A) evaluation system and SIR measurement system can conduct the customization design integration test either with King Son made or 3rd party brand Temperature Cycling Test Chamber, Thermal Shock Test Chamber, HAST+ Highly Accelerated Stress Test Chamber, Constant Temperature and Humidity Test Chamber or Electric-dynamic Shaker.

The VMR series (VMR-S, VMR-F, VMR-3A) evaluation system in each interaction test maximum can integrate with up to 8 test chambers.

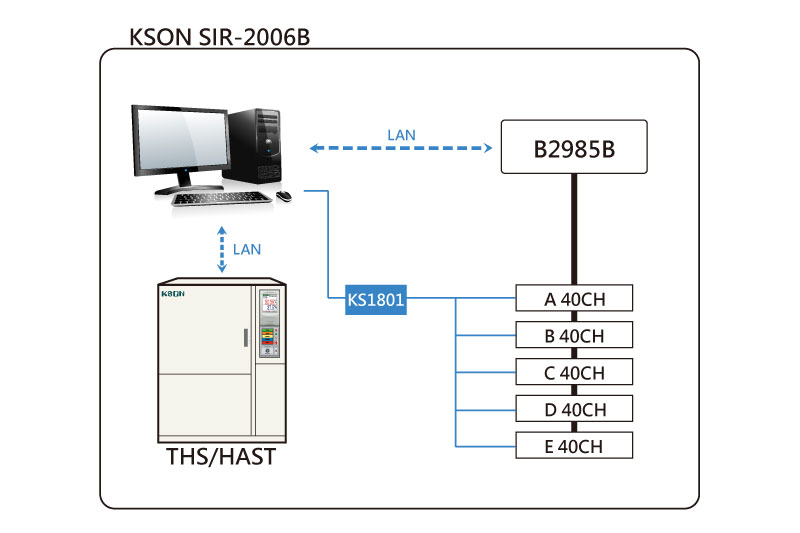

The SIR measurement system in each interaction test maximum can integrate with up to 5 test chambers.

King Son THS Programmable Constant Temperature and Humidity Test Chamber + King Son SIR Surface Insulation Resistance Measurement System

King Son THS + SIR integration test is designed to conduct high-temperature and high-humidity 85℃/85% RH for product life aging test, the product under THS + SIR test becomes brittle, and its characteristics decline.

King Son SIR is a scanning type designed Surface Insulation Resistance Measurement System(SIR-2006B-250V) that can expand the migration measurement up to 200 channels and breaks through the limits that the traditional scanning surface insulation resistance measurement system cannot records the migration ending time and also cannot records the happened time of migration, that customers can get the maximum production benefit with the least minimum equipment cost.

King Son TSC Thermal Stress Complex Test Chamber interaction test with King Son VMR-S Conductor Resistance Evaluation System – Standard

King Son TSC + VMR-S integration test is applicable for various automotive electronics materials, parts, and components soldering joints tests includes fixed-point temperature test, high temperature and high humidity test, high and low temperature thermal shock test, high and low temperature rapid temperature cycle test, highly accelerated life aging test, and various environmental reliability tests.

King Son TSC + VMR-S integration test is capable to conduct environmental reliability tests for automotive electronics material, parts, and components such as FPC, PCBA, resistors, inductors, capacitors, BGA & CSP solder joints, and advanced semiconductor packaging tests (Sip, SoC, WLP, PLP, FOWLP, 3D-IC, FCin MCep, FCBGA, Fc CSP, etc.) that assist customers to analyze the parts, components soldering joints reliability evaluation in the finished product quickly and effectively.

King Son HAST+ Highly Accelerated Stress Test Chamber interaction test with King Son SIR Surface Insulation Resistance Measurement System

King Son HAST + interaction test with King Son SIR is designed to provide high humidity 85% R.H, increase the test temperature and pressure to accelerate the aging test of automotive electronics parts, components, materials and shorten the test time of life test.

King Son SIR Surface Insulation Resistance Measurement System interaction test with King Son THS Programmable Constant Temperature and Humidity Test Chamber, ATSK Thermal Shock Test Chamber, HAST+ Highly Accelerated Stress Test Chamber

-

King Son THS Programmable Constant Temperature and Humidity Test Chamber

[Online Catalog]

King Son THS Programmable Constant Temperature and Humidity Chamber is designed to carry out condensation and dew condensation tests for automotive electronics and damp heat temperature cycle test, combined temperature and humidity cycle test, humidity resistance test for electric vehicles.

Test standards: ISO16750, LV 124, AECQ-200, IEC60068-2], besides that, the accelerated aging test, temperature gradient test, Specify temperature change rate temperature cycle test, heat soak temperature cycle test are also included to meet the test requirements for Automotive and Vehicle Electronics.

-

King Son TSC Thermal Stress Complex Tester

[Online Catalog]

King Son TSC Thermal Stress Complex Tester is designed to conducts the test requirements of ISO16750 (including temperature cycle test, rapid temperature change test with specified conversion time), LV124 (include temperature rise and fall operation test, temperature cycle test, temperature shock test), and AECQ-100, AECQ-200 tests (include [TC] temperature cycle test, [PTC] power temperature cycle test), AECQ-200 thermal shock and other rapid temperature cycle test (4 ~ 30 ℃/min). -

King Son ESS Environmental Stress Screening Test Chamber

[Online Catalog]

King Son ESS Environmental Stress Screening Test Chamber is designed to conduct a full inspection of the active, passive parts, components and PCBA (printed circuit board assembly) of automotive electronics, through rapid temperature change stress (5°C/min, 10°C/min, 15°C/min, 20°C/min), to find out and screen out the potentially defective in parts, components and manufacturing process flaws to improve overall quality and reliability. -

King Son HAST+ Highly Accelerated Stress Test Chamber

[Online Catalog]

King Son HAST+ Highly Accelerated Stress Test Chamber is designed to conduct constant high-humidity environment (85% R.H.) test, which increase the temperature and pressure, and perform accelerated life tests [JESD22-A110, JESD22-A118] for automotive electronics parts, compoents and materials, effectively shortening the traditional high-temperature and high-humidity test time [JESD22-A101], It can also perform forced moisture absorption and destructive tests under high pressure (100% R.H.) [JESD22-A102]. -

King Son VTH Agree Test Chamber

[Online Catalog]

King Son VTH Agree Test Chamber is an environmental test chambers that is designed to combine temperature and humidity testing with vibration testing to simulate the changes and the damages on the product in the natural environment by the three physical stresses - temperature, humidity and vibration, used to evaluate the product's reliability and adaptability to the environment, which can simultaneously conduct temperature and humidity change testing and random vibration testing to identify the weakness of product’s design and to find out the defects of the product. -

King Son BAT-TS Environmental Test Chamber for Secondary Lithium-Ion Batteries

[Online Catalog]

Charging and discharging tests of batteries, such as lithium-ion batteries, are important tests to evaluate the life of batteries.During the test, there is a possibility of gas leakage from the battery, ignition, smoking, or destruction. King Son Environmental Test Chamber for Secondary Lithium Ion Batteries is safe and environmentally friendly tester will strongly support your testing.

Industry Integration Test

King Son THS Programmable Constant Temperature and Humidity Test Chamber + King Son SIR Surface Insulation Resistance Measurement System

King Son THS + SIR integration test is designed to conduct high-temperature and high-humidity 85℃/85% RH for product life aging test, the product under THS + SIR test becomes brittle, and its characteristics decline.

King Son TSC Thermal Stress Complex Tester + King Son VMR-S Conductor Resistance Evaluation System - Standard

King Son TSC + VMR-S integration test is designed to conduct high-speed measurement, recording, and data analysis for various electronic parts, components, materials, and its soldering joints tests.

King Son HAST+ Highly Accelerated Stress Test Chamber + King Son SIR Surface Insulation Resistance Measurement System

King Son HAST+ and SIR integration test is designed to provide high humidity 85% R.H, increase the test temperature and pressure to accelerate the aging test of automotive electronics parts, components, materials and shorten the test time of life test.