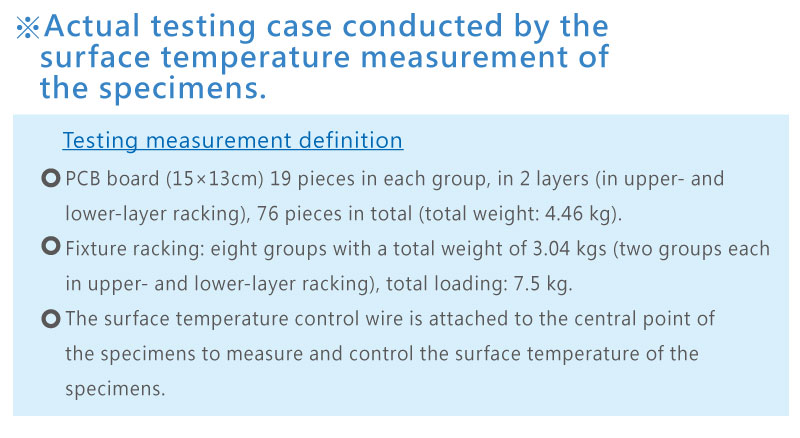

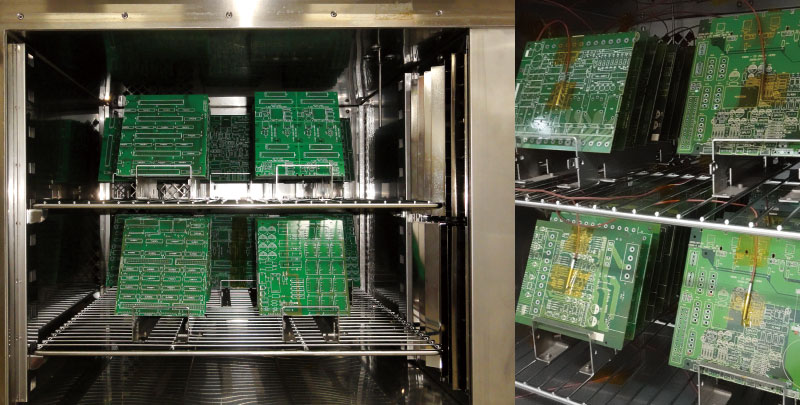

King Son's environmental testing chambers that meet the requirements of international testing standards is designed in with surface temperature detection and temperature cycle temperature change rate by testing specimens to conduct product's liability testing.

King Son 's Advanced Series THS, TSC, ATSK, HAST+ testing chambers leads the industry with superior technology.

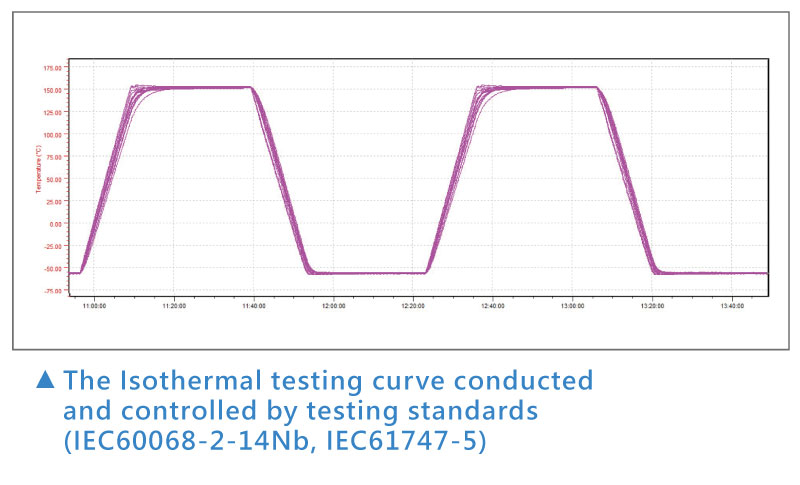

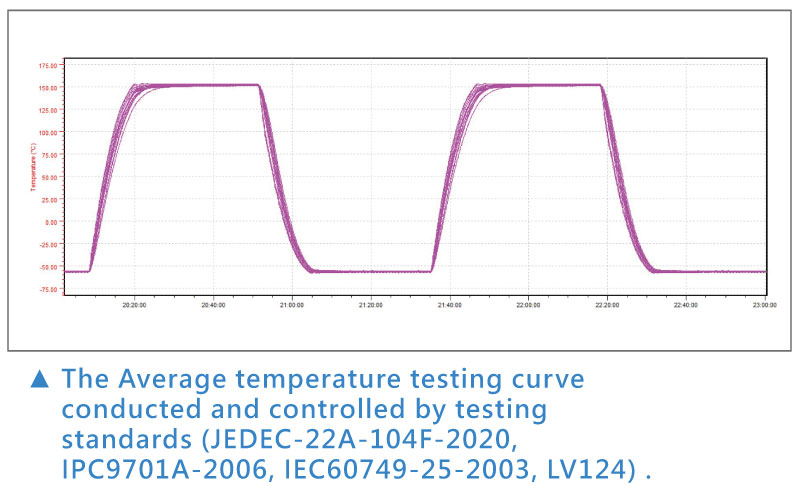

The specific requirements by international testing standards on the surface temperature control of testing specimens include JESD22-A104F, IPC9701, IEC60068-2-14, IEC60068-3-5.

The latest new testing requirements for the dwell time of testing specimens is when the internal temperature of DUT, Devices Under Test, reaches the set temperature and stabilizes that.

Temperature cycle testing standards and temperature change control is based on the surface temperature of the specimens (DUT, Device Under Test) JEDEC-22A-104F、IEC60749-25、IPC9701、ISO16750、AEC-Q100、LV124、GMW3172

Conduct the temperature cycle test by the feature of surface temperature control of the specimens.

2. Dual modes, available to select the heating and cooling temperature change rate.

3. The temperature change rate can be setup by choosing either Total temperature change time or Temperature change rate per minute to set the heating and cooling rate for the testing specimens.

*Total temperature change time (minute) complying with international testing standards JESD22-A104F、MIL-STD-883K、CR200315、ED-4702A.

*Temperature change rate per minute (℃/minute) complying with international testing standards IEC 60749、IPC-9701、Bellcore-GR-468、MIL-2164.

4. The reciprocal of the dwell time can be determined by the surface temperature of the specimens.

5. The number of channels used to control the surface temperature of the specimen: 8 channels.

The overlapping comparison chart of different loading temperature cycle testing curves

150℃(30min)←→-55℃(30min)、Ramp:15℃/min

7.5 Kg(Fixture:3.04 kg+PCB:4.46 kg)

5.0 Kg(Fixture:3.04 kg+PCB:1.96 kg)

2.5 Kg(Fixture:1.52 kg+PCB:0.98 kg)